- 产品描述

千和精密机械剥漆刀,该产品选用碳化钨材料精密加工而成。硬度高,抗弯强度高达。采用的工艺设备对产品的内孔及两端入出线口进了镜面研磨处理,内孔表面粗糙度为Ra0.1,两端弧度处表面粗糙度高达Ra0.025。我们的工艺了内孔与入出线口弧度的自然过渡,根据孔径大小选择了科学合理的弧度,并保持高度一致性,不伤基体,甘肃加工剥漆刀现货,从而了过线的通畅。是电机,甘肃加工剥漆刀现货、电器、仪表、变压器,甘肃加工剥漆刀现货、电子、家用电器及电动工具等线圈制造和维修行业理想的刮漆工具。杭州千和剥漆刀是电机刮漆的理想工具。甘肃加工剥漆刀现货

The enameled wire stripping machine adopts a high-speed stripping cutter head made of new technology and extra hard materials, which can completely remove any hard insulating paint, enamel paint, ML, lsonel, etc. on the wire surface without damaging the copper wire itself. It is especially suitable for use when the paint needs to be peeled to the bottom of the coil. The operation is convenient and the effect is excellent. The machine is equipped with a paint peeling length termination device, which can accurately control the paint peeling length of the enameled wire and automatically adjust the radian of the wire body. In the absence of serious pollution and harm, the paint peeling work is fast and safe. It is an ideal paint scraping tool for coil manufacturing and mechanical maintenance industries such as motors, electrical appliances, meters, transformers, electronics, household appliances and power tools.山东直销剥漆刀金刚石材料刀头剥漆刀。

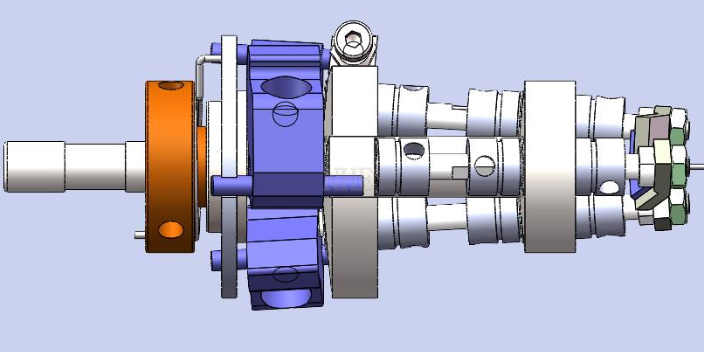

本实用新型提供的漆包线剥漆机,1.漆皮经吸尘筒进行集中收集,避免漆皮污染整套设备。2.驱动装置与安装座位于所述基板的同侧,能够减小漆包线剥漆机的布置空间。3.盖板的中心具有圆形通孔,且与安装座连接,利于漆包线在出线/进线时保持水平。The paint stripping machine for enameled wire provided by the utility model comprises the following steps: 1. The paint skin is collected in a centralized manner by a dust collector to avoid the paint skin polluting the whole set of equipment. 2. The driving device and the mounting base are located on the same side of the substrate, which can reduce the layout space of the enameled wire stripper. 3. The center of the cover plate has a circular through-hole and is connected with the mounting base, which is conducive to keeping the enameled wire horizontal when outgoing / incoming.

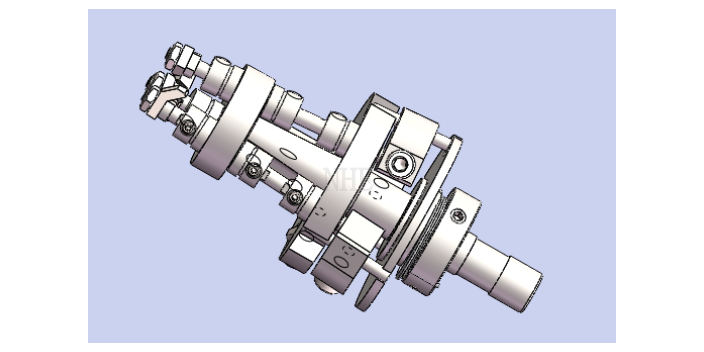

剥漆刀剥漆机本实用新型提供的漆包线剥漆机,剥漆刀一端通过旋转轴连接在基板上,剥漆刀的另一端连接在安装座的容纳腔内;基板与旋转轴通过**轴承连接,剥漆刀的另一端通过*二轴承与所述安装座连接,所述**轴承与*二轴承的设置能够减小剥漆刀转动过程中的摩擦力,同时起到支撑作用;旋转轴的与剥漆刀连接的一端通过*三轴承与安装座连接,能够对所述旋转轴与剥漆刀的连接处起到支撑与固定作用,并且能够减小所述连接处的相对晃动。千和剥漆刀剥皮非常均匀。

Paint stripping knife and paint stripping machine the paint stripping machine for enameled wire provided by the utility model comprises: one end of the paint stripping knife is connected to a base plate through a rotating shaft, and the other end of the paint stripping knife is connected to a receiving cavity of a mounting base; The base plate is connected with the rotating shaft through a front-end bearing, and the other end of the paint stripping knife is connected with the mounting base through a second bearing. The front-end bearing and the second bearing can reduce the friction force during the rotation of the paint stripping knife and play a supporting role at the same time; One end of the rotating shaft connected with the paint stripping knife is connected with the mounting seat through the third bearing, which can support and fix the connection between the rotating shaft and the paint stripping knife, and reduce the relative shaking at the connection.杭州千和剥漆刀效率高。广东磁阻尼剥漆刀市场价

杭州千和剥漆刀快递发货快。甘肃加工剥漆刀现货

漆包线是电机、电器、家用电器、电子、仪表电磁绕组的基础和关键材料,使用时需要将线头的绝缘层去除。一般通过剥漆刀对漆包线进行剥漆,由于剥漆刀在工作过程中一直处于旋转状态,容易出现晃动现象,可能对漆包线造成过度剥漆或者剥漆不完整的现象。漆包线是绕组线的一个主要品种,由导体和绝缘层两部组成,裸线经退火软化后,再经过多次涂漆,烘焙而成。但要生产出既符合标准要求,又满足客户要求的产品并不容易,它受原材料质量,工艺参数,生产设备,环境等因素影响,因此,各种漆包线的质量特性各不相同,但都具备机械性能,化学性能,电性能,热性能四大性能。甘肃加工剥漆刀现货

杭州千和精密机械有限公司一直专注于工装夹具、张力器、全自动绕线机零部件、自动化设备零部件、伺服电机以及传感器的设计生产组装;张力器、传感器、伺服电机以及驱动控制的技术开发;工装夹具的设计;工装夹具及配件、五金机电、机械自动化设备的销售。,是一家机械及行业设备的企业,拥有自己独立的技术体系。公司目前拥有专业的技术员工,为员工提供广阔的发展平台与成长空间,为客户提供高质的产品服务,深受员工与客户**。公司业务范围主要包括:磁力张力器、伺服张力器,气动剪刀、剥漆刀,线嘴、导针,绕线机治具等。公司奉行顾客至上、质量为本的经营宗旨,深受客户**。一直以来公司坚持以客户为中心、磁力张力器、伺服张力器,气动剪刀、剥漆刀,线嘴、导针,绕线机治具市场为导向,重信誉,保质量,想客户之所想,急用户之所急,全力以赴满足客户的一切需要。

杭州千和精密机械有限公司成立于2006年,开发设计、生产、销售各类全自动绕线机配件以及小功率高速直流伺服电机及驱动控制。公司现有四大系列产品的研发生产:1、各类伺服张力器、磁力张力器及张力测量全系列产品;2、超硬材料绕线导针系列;3、气动剪刀及绕线治具系列;4、小功率高速直流伺服电机及驱动控制。

公司产品已应用于国内**各大公司的自动绕线装备上:有田中精机,日本电产,松下,TDK,胜美达,BOSCH博世、中达等等**公司;公司主要产品张力器,绕线导针,气动剪刀,剥漆刀等销往29个国家和地区。

公司现设有杭州千和精密公司,德清千和精密工厂,深圳办事处。现有办公和厂房6000余平方,员工100余名,其中产品研发人员15人,有5个生产车间。

“诚信、务实、创新,做**客户满意的产品”

**的质量管理标准应用于产品实现的全过程,努力打造“硬、精、尖”的产品,热忱服务于国内外客户。欢迎来到杭州千和精密机械有限公司网站,我公司位于与苏州并称“苏杭”,素有“上有天堂下有苏杭”美誉的杭州。 具体地址是浙江杭州拱墅区公司街道地址,负责人是张光辉。

主要经营磁力张力器、伺服张力器|气动剪刀、剥漆刀|线嘴、导针|绕线机治具。

单位注册资金:人民币 100 万元 - 200 万元。

本公司在机械产品这一领域倾注了无限的热忱和激情,公司一直以客户为中心、为客户创造价值的理念、以品质、服务来赢得市场,衷心希望能与社会各界合作,共创成功,共创辉煌,携手共创美好明天!

本页链接:http://www.cg160.cn/vgy-94963166.html

以上信息由企业自行发布,该企业负责信息内容的完整性、真实性、准确性和合法性。阿德采购网对此不承担任何责任。 马上查看收录情况: 百度 360搜索 搜狗

- 产品推荐

- 鄂尔多斯无负压供水设备 罐式无负压供水设备 聊城无负压供水设备 罐式无负压供水设备 混凝土抗压强度智能检测 宜春扣件试验机 疲劳试验机 济宁无负压供水设备 无负压二次供水设备 安全泄压阀AX742X代理_低阻减压阀_阀门型号丰富 长沙 6舱 酒店隧道式洗衣龙 抽屉断路器流水线 青岛流水线设备 可承载力强 沈阳供水无负压设备 箱式无负压供水设备 和田无负压变频供水设备 罐式无负压供水设备 镇江无负压供水设备厂家 罐式无负压供水设备 HXS-100KG|可定制量程|宁波柯力称重传感器特点 BSS-250KG|厂家供应|上海托利多料仓称重传感器

- 相关文章

- 中国台湾节能剥漆刀现货 真诚推荐 杭州千和精密机械供应陕西微型剥漆刀厂家 真诚推荐 杭州千和精密机械供应中国台湾微型剥漆刀 推荐咨询 杭州千和精密机械供应广东巨型导针线嘴商家 推荐咨询 杭州千和精密机械供应湖北销售剥漆刀现货 抱诚守真 杭州千和精密机械供应中国澳门工业导针线嘴 抱诚守真 杭州千和精密机械供应江苏定制剥漆刀 信息推荐 杭州千和精密机械供应甘肃购买导针线嘴哪里买 抱诚守真 杭州千和精密机械供应甘肃通用导针线嘴供应商家 真诚推荐 杭州千和精密机械供应陕西巨型导针线嘴现货 信息推荐 杭州千和精密机械供应巨型导针线嘴调试 推荐咨询 杭州千和精密机械供应江苏智能导针线嘴哪里买 抱诚守真 杭州千和精密机械供应

- 我要给“甘肃加工剥漆刀现货 推荐咨询 杭州千和精密机械供应”留言

- 更多产品