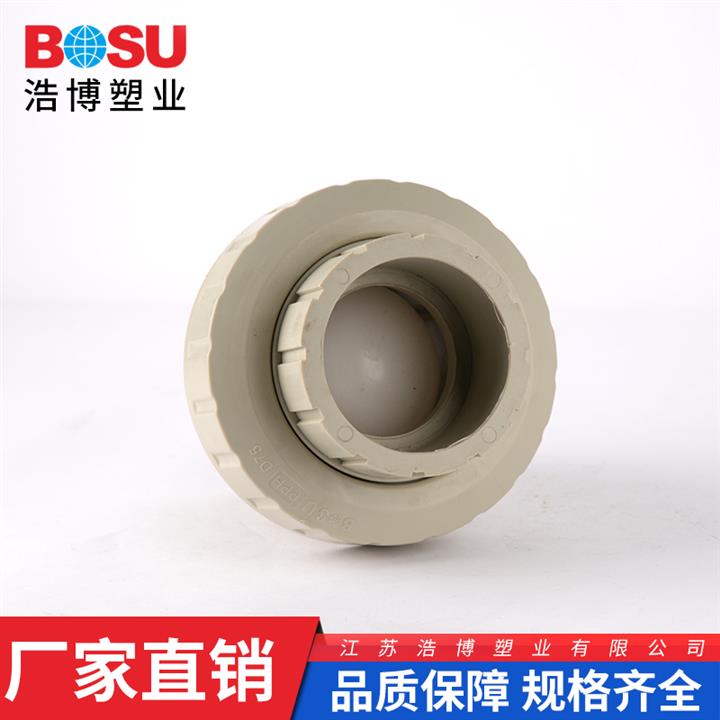

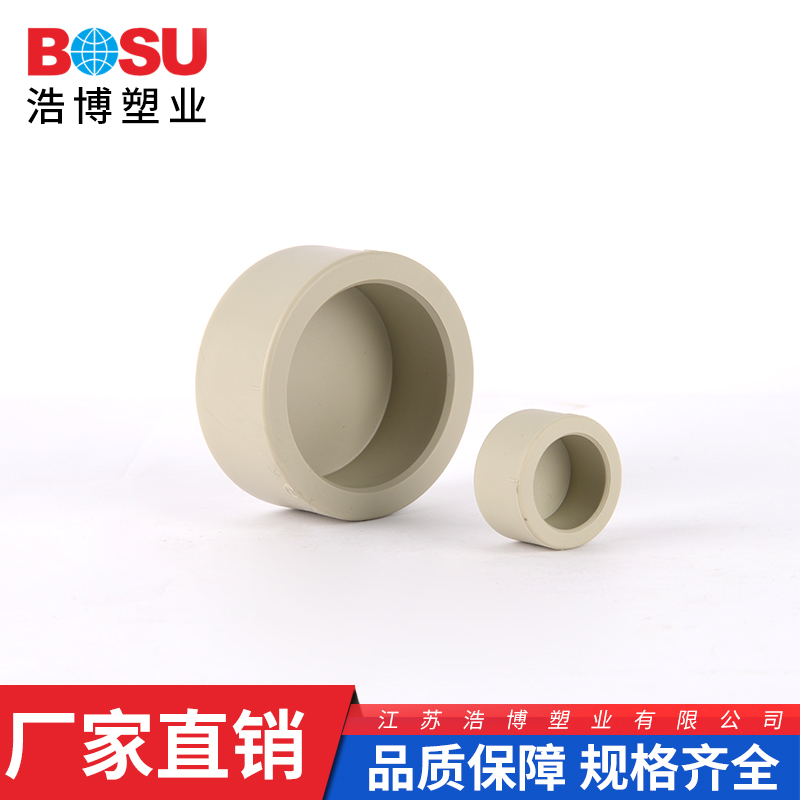

- 产品描述

三 焊接工艺要求 Welding process requests

1 焊接材料与管道材料必须相同

2 焊接温度,聚丙烯210~230℃,聚乙烯195~210℃(具体情况根据室外温度而定)。

3 管道焊接处必须清洁干净。

4 焊缝表面应平整,不准有波纹形及焊缝弯曲现象。

5 焊条排列应紧密,不准有空隙。

6 焊条和管材及管件必须处于同时熔融状况进行焊接,但不应有烧焦或分解现象。

7 焊条应垂直焊缝并略施加一定作用力,知道焊条与制品熔接为止。

1.Welding rod material with pipe material must same.

2.Welds temperature,Polypropylene will be 210~230℃,Polyethylene will be 195~210℃.

3.Pipe welds place must clean.

4.Brazing seam surface should neat,Nots permit have slop lines shape and brazing seam bended phenomenon.

5.Welding rod alines should tightness,Not permit free crack.

6.Welding rod and tubing and administer must be in meanwhile melt status proceed weld,But not does due burn burner or anglyse phenomenon.

7.Welding rod should plumb brazing seam and slightly exert certain action and reaction,Tills welding rod with ware melt meet up to.

每一加工工序又可通过不同的塑性加工方法来实现。例如管材的弯曲加工,可分为绕弯、压弯、 推弯、滚弯等方法。

任何一家企业,无论其所提供的产品是量化的物,还是无形的服务,终都将受到市场和普通消费者的检验。

一 管材和管件连接 Tubing and administer a connection

1 所有管道端面必须加工平齐,并与管道中心线垂直。

2 采用碰焊连接的管道必须开坡口,碰焊管件厚度2~8mm,坡角为a=85-75°,管件厚10~20mm,坡角为a=75-65°具体形式见图:

3 对于承插连接的管子与管件,承心内侧应有1/32锥度。

4.法兰端密封面与管子中心线垂直偏差0~1°,法兰连接端的密封面的不水平度应小于0.3mm,承心的垂直偏心度应小于1mm。

5.法兰与法兰管件连接,配合面间应加密封垫片。

6.配件与配件间采用螺丝连接的,螺丝松紧程度应基本一致。

1.All pipe end face must process calm down neat,And with pipe camber line plumb.

2.Adopts touch weld copular pipe must open slope,Will touch weld administer a thickness 2~8mm,Slope corner for a=85-75°,Tubing will be thick 10~20mm,Slope corner for a=75-

65°concrete form see picture.

3.Towards bearing inserts copular pipe and administer,Dues 1/32 Zhui dus inner bearing heart.

4.Flange will hold dense cover with pipe camber line plumb deflection 0~one°,Flange connects hold’s seal up microbus not level degree should be less than 0.3mm,Bearing heart’s plumbs prejudicial should be less than 1mm.

5.Flange with flange administers a connection,Cooperates with between should plus seal up shim.

6.Accessory with adopts screw copular between accessory,Screw segree of tightness extent basically unanimously.

江苏浩博塑业有限公司座落在江苏省东台市城东工业园区,占地53280平方米。我们以太阳板制造、半导体制造、化工、炼铁、环保、生化、水族馆/海洋、医药品制造领域的管路应用为目标 ,以树立各类阀门、管件、管材的生产销售为一体的**企业及****阀门行业的****技术企业。 我们以“科技创造未来”为技术研发宗旨,以“品质创造市场”为品质宗旨,以“品牌创造**”为市场营销宗旨,力争开拓创新,为**客户提供全面优质的服务。

欢迎来到江苏浩博塑业有限公司网站,我公司位于有“东方湿地之都”之称的淮剧主要的发源地—盐城市。 具体地址是江苏盐城东台市公司街道地址,负责人是李幼娇。

主要经营PPH管。

我司主要供应:建材 管材管件 聚丙烯管 等,我们的产品质量优等,种类齐全,我的销售范围广,我们的服务客户满意;如果您对我公司的产品有兴趣,请在线留言或者来电咨询。

本页链接:http://www.cg160.cn/vgy-54530908.html

以上信息由企业自行发布,该企业负责信息内容的完整性、真实性、准确性和合法性。阿德采购网对此不承担任何责任。 马上查看收录情况: 百度 360搜索 搜狗

- 产品推荐

- 悬空双轨道雨篷 电动推拉雨棚定制 下雨伸缩 路沿石 汉中滨州青石材 种类多样 工厂供应 防辐射铅门价格 铅门供应 选材优良 晋中森林绿石材 深绿色石材 广场地铺用石板 日照森林绿石材 深绿麻花岗岩 园林建筑工程 晋城森林绿石材 花岗岩石材 石材异形加工 威海森林绿花岗岩 石材厂家 园林建筑工程 资阳内螺旋钢管 螺旋管 吕梁森林绿花岗岩厂家 深绿麻石材厂家 园林建筑工程 墙面防水涂料厂家 k11防水涂料 全国发货 双环氧供应 螺旋管 山西防静电地板生产 直铺防静电地板 免费测量现场

- 相关文章

- 北京PPH管加盟 拉萨PPH弯头热熔对焊公司 浩博塑业太原PPH管生产厂家 长春PPH弯头厂家 浩博塑业秦皇岛PPH管公司 沈阳PPH弯头热熔承插厂商 浩博塑业淄博PPH管公司 包头PPH90°弯头热熔对焊 浩博塑业柳州PPH管零售 太原PPH弯头厂家 江苏浩博塑业嘉兴PPH管加盟 深圳PPH弯头45°热熔对焊厂家 浩博塑业昆明PPH管厂商 福州塑料弯头厂家直销 浩博塑业郑州PPH管厂商 北海PPH45°弯头热熔承插厂商 浩博塑业惠州PPH管厂家 绍兴塑料弯头厂家直销 江苏浩博塑业北海PPH管加盟 温州PPH弯头热熔承插厂家 浩博塑业大连PPH管生产厂家 石家庄PPH弯头公司 浩博塑业烟台PPH管品牌 潮州PPH弯头热熔承插批发 浩博塑业

关于江苏浩博塑业有限公司

商铺首页 |

更多产品 |

联系方式

江苏浩博塑业有限公司座落在江苏省东台市城东工业园区,占地53280平方米。我们以太阳板制造、半导体制造、化工、炼铁、环保、生化、水族馆/海洋、医药品制造领域的管路应用为目标 ,以树立各类阀门、管件、管材的生产销售为一体的**企业及****阀门行业的****技术企业。 我们以“科技创造未来”为技术研发宗旨,以“品质创..

- 我要给“威海PPH管批发品牌 PPH管道”留言

- 更多产品