- 产品描述

PET吸塑片材PET单层片材、PET共挤双层片材,PET双面高透明材料等用用于塑料包装行业的片材。PET厚板材生产线PET厚板材采用普通APET原料以及改性PET原料加工,由于其性价比比PC较优越,在许多领域逐渐代替PC耐力板,用于建筑、装饰、广告等。

公司拥有完善的创新机制,有专门研发机构和试制车间,连年推出新产品,为中国塑料机械和塑料制品的发展做出了重大贡献,受到了、质检总局等部委的大力扶持。

重点针对PET产品的回收再利用的性质,反复实验和研发出螺杆新式结构,使物料在机筒中高速剪切,多段*特的剪切方式使物料在短时间达到多层快速塑化,*干燥结晶,同时设计创新的式自动排气装置,使回收料的潮气和水分在主机运转过程中自动排除,成功解决了生产制品结块和气泡的难题,在PET回收方面**了重大突破,达到物料**回收料,且*干燥结晶的世界水平。

公司以诚信为立业之本,以高品质的产品、以的服务对待每一个用户。Pet sheet production line

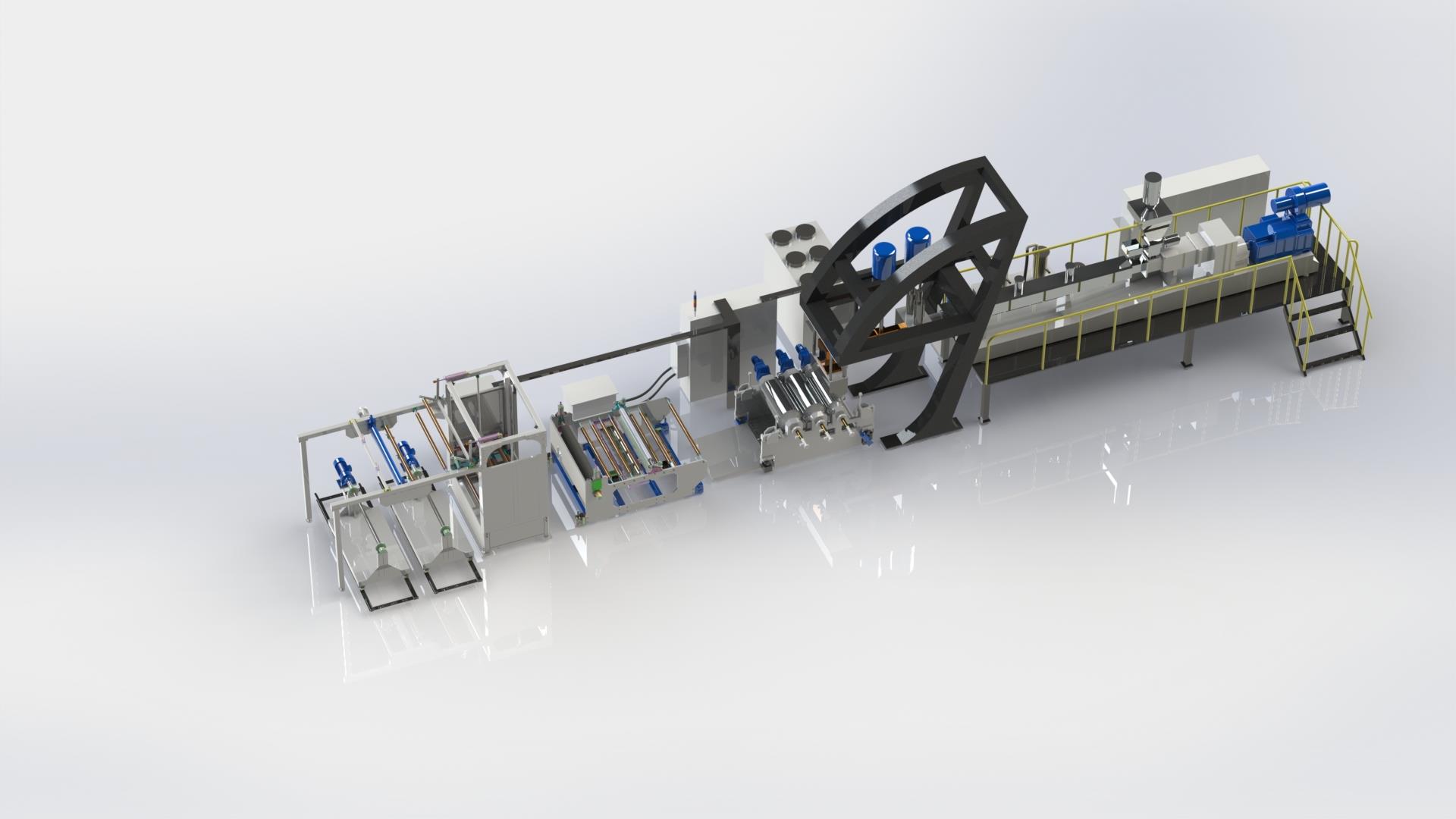

The PET sheet production line produced by our company has been widely used in more than ten countries and regions around the world. Its high quality, large output and strong stability are favored by customers.

青岛欧瑞泰科塑料机械有限公司制造流延膜设备以及双拉同步拉伸设备。The Pet sheet production line adopts the parallel twin-screw extruder screw and the barrel design adopts the “building block type” structure. It has good interchangeability and can be used in any combination according to different material processing techniques to meet the different needs of customers. The cylinder is made of nitrided steel and bimetal, which is wear-resistant and corrosion-resistant and prolongs the service life. The threaded components are made of nitrided steel and high-speed steel. The curve is computer-aided design and unique processing technology to ensure the thread working section. The normal tooth surface clearance and self-cleaning property; the specially designed connection mode and transmission device enhance the thread component and the mandrel strength. The above measures achieve uniform material dispersion, good mixing and plasticizing effect, and short material retention time. The conveying efficiency is high and the output is large.

青岛欧瑞泰科塑料机械有限公司拥有国内的研发团队,其中5人,13人,科研人员36人。公司先后与北京化工学院、哈尔滨工业大学、青岛科技大学等科研院校合作,有力地促进了科研成果、技术、资金、人才等创新要素在欧瑞泰科的聚合。

青岛欧瑞泰科塑料机械有限公司始建于1991年,总占地面积15万平方米。主要产品:塑料机械,双向拉伸生产线,电池隔膜生产线,石头纸生产线,同步拉伸机,BOPP线,BOPET线,流延膜生产线,PVB生产线,CPP流延线,eva生产线,tpu生产线,pvdf生产线,压延片材生产线,PET片材线,PVC片材线等。产品含盖机械、化工、电子、塑料、纺职、钢铁等领域。

欢迎来到青岛欧瑞泰科塑料机械有限公司网站,我公司位于中国着名的品牌之都—青岛市 具体地址是山东青岛胶州市公司街道地址,负责人是赵先生。

主要经营青岛欧瑞泰科塑料机械有限始建于1991年,总占地面积15万平方米。主要产品:pvb胶膜生产线,双向拉伸膜生产线,ASA薄膜生产线,cpp薄膜生产线,pet片材生产线,pvdf薄膜生产线。产品含盖机械、化工、电子、塑料、纺职、钢铁等领域。。

本公司在机械产品这一领域倾注了无限的热忱和激情,公司一直以客户为中心、为客户创造价值的理念、以品质、服务来赢得市场,衷心希望能与社会各界合作,共创成功,共创辉煌,携手共创美好明天!

本页链接:http://www.cg160.cn/vgy-54371583.html

以上信息由企业自行发布,该企业负责信息内容的完整性、真实性、准确性和合法性。阿德采购网对此不承担任何责任。 马上查看收录情况: 百度 360搜索 搜狗

- 产品推荐

- 呼和浩特双支架变频通风机定制 永动电机 性能完善 青海气胎离合器公司 摩擦片安装在铝质底座上-散热性好 广州数控高压清洗机 除砂清洗机 欢迎电话咨询 液压凿岩机配件 石河子传动轴厂 河池钎尾导套批发 基础锚固施工 地质勘探 广元冲洗头 福州不锈钢变频通风机厂家 永动电机 支持定制 液压凿岩机配件 遂宁传动轴公司 三轮车流水线 自动化程度高 临沂装配流水线 自动压袋机 定制 沈阳三通换向阀 抚州粘度计 海富达番茄酱测试粘度计 凿岩机配件 隧道岩石破碎 北京缓冲活塞报价

- 相关文章

- 萍乡EVA/POE薄膜生产线EVA胶膜生产线 青岛欧瑞泰科塑料机械有限公司青岛欧瑞泰科塑料机械有限公司 盘锦POE胶膜生产线POE胶膜生产线郑州干法双向拉伸隔膜生产线锂电池隔膜生产线设备电话 青岛欧瑞泰科塑料机械有限公司西宁耐老化抗紫外线土工格栅设备生产线定制 青岛欧瑞泰科塑料机械有限公司潮州pvb胶膜生产线设备 青岛欧瑞泰科塑料机械有限公司宜春pc光学片材生产线pc光学片材生产线 青岛欧瑞泰科塑料机械有限公司 光学片材生产线青岛欧瑞泰科塑料机械有限公司 郑州tpu胶膜生产线常州大产量pet片材生产线设备 青岛欧瑞泰科塑料机械有限公司青岛欧瑞泰科塑料机械有限公司 安阳pmma光学片材生产线pmma光学片材生产线烟台耐候膜生产线 青岛欧瑞泰科塑料机械有限公司牡丹江O膜生产加工设备生产线O膜生产线 青岛欧瑞泰科塑料机械有限公司青岛欧瑞泰科塑料机械有限公司 韶关同步拉伸机膜片同步拉伸机

关于青岛欧瑞泰科塑料机械有限公司

商铺首页 |

更多产品 |

联系方式

青岛欧瑞泰科塑料机械有限公司始建于1991年,总占地面积15万平方米。主要产品:塑料机械,双向拉伸生产线,电池隔膜生产线,石头纸生产线,同步拉伸机,BOPP线,BOPET线,流延膜生产线,PVB生产线,CPP流延线,eva生产线,tpu生产线,pvdf生产线,压延片材生产线,PET片材线,PVC片材线等。产品含盖机械、化工、电子、塑料、纺职、..

- 我要给“西安国产pet片材生产线设备 PET片材挤出线”留言

- 更多产品

相关分类